Plastic waste recycling plant in Lahti

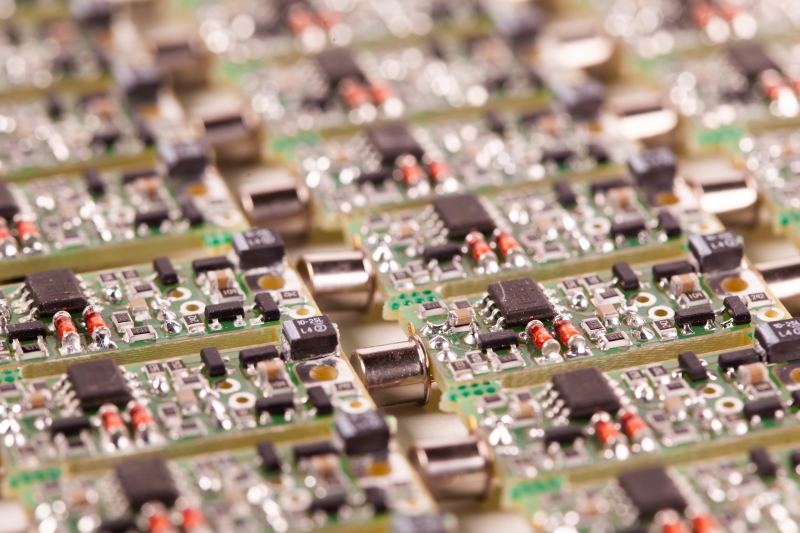

PlastEco Ltd- start-up company based in Lahti is building a chemical recycling plant for plastic waste. The technology applied produces 1000 liters of clean plastic oil from 1000 kilograms of plastic waste, which is completely reusable as a raw material of plastics. The processing capacity of the first plant in Lahti is 5 tonnes per day.

Firstly, Salpakierto Ltd, the local waste management company, receives the waste and sorts plastic materials from mixed waste. Afterwards, the plastics are sliced and pelleted, and then processed into its original raw materials thermo-chemically (pyrolysis).

The technology provider is enespa GRT innovation GmbH. Its core expertise lies in plant engineering and the associated industrial services using pioneering technologies.

Global Ecosolutions Ltd is a founder of PlastEco Ltd. It has been responsible for the project development including funding arrangements. The management services are provided by Global EcoSolutions .